The landscape of fine jewelry has undergone a seismic shift, largely driven by the phenomenal rise of lab-grown diamonds. In this new era, no country is more pivotal than India. Already the global epicenter for the cutting and polishing of nearly 90% of the world’s diamonds—both mined and lab-grown—India’s expertise is now focused on perfecting the art of Chemical Vapor Deposition (CVD) diamond manufacturing.

CVD technology offers an incredible blend of quality, ethical sourcing, and value, but navigating this market requires a discerning eye. As the supply chain matures, not all CVD diamonds are created equal. High-quality production from top Indian manufacturers utilizes proprietary growth methods and cutting-edge polishing techniques to produce stones that are chemically, physically, and optically identical to the finest mined diamonds.

This expert guide will take you beyond the foundational 4Cs, revealing the specific quality indicators, certification requirements, and provenance checks you need to employ to confidently identify and procure premium CVD diamonds from the Indian market.

Section 1: The Indian Advantage: A Hub of Precision and Expertise

To understand the quality of an Indian-grown CVD diamond, you must first appreciate the manufacturing infrastructure that underpins it. India’s dominance in the global diamond industry is not accidental; it is built on centuries of craftsmanship and generations of specialized skill, particularly concentrated in and around Surat, Gujarat—the “Diamond Capital of the World.”

The Legacy of the Master Cutter

When a rough CVD diamond leaves the growth chamber, its future brilliance depends entirely on the skill of the cutter. This is where India provides an unparalleled advantage. The specialized workforce in Surat possesses a collective expertise in diamond geometry, symmetry, and light performance that is unmatched globally.

For CVD diamonds, this legacy translates into:

- Optimized Light Return: High-quality Indian cutting and polishing techniques are calibrated to maximize the diamond’s brilliance, fire, and scintillation. They prioritize precision cutting over simply maximizing carat weight, a crucial distinction between premium and lower-quality offerings.

- Technological Integration: Leading Indian manufacturers have invested heavily in 4th-generation laser processing systems (such as the Hallmark Green Edge and Evoq machines). These high-precision tools utilize advanced software to map the rough stone and execute cuts with microscopic accuracy, minimizing material waste and ensuring flawless alignment of facets. This modern marriage of traditional skill with laser precision is a hallmark of the highest-quality CVD production.

The first step in identifying a premium CVD diamond is recognizing that its exceptional Cut grade is directly tied to this highly skilled and technologically advanced Indian ecosystem.

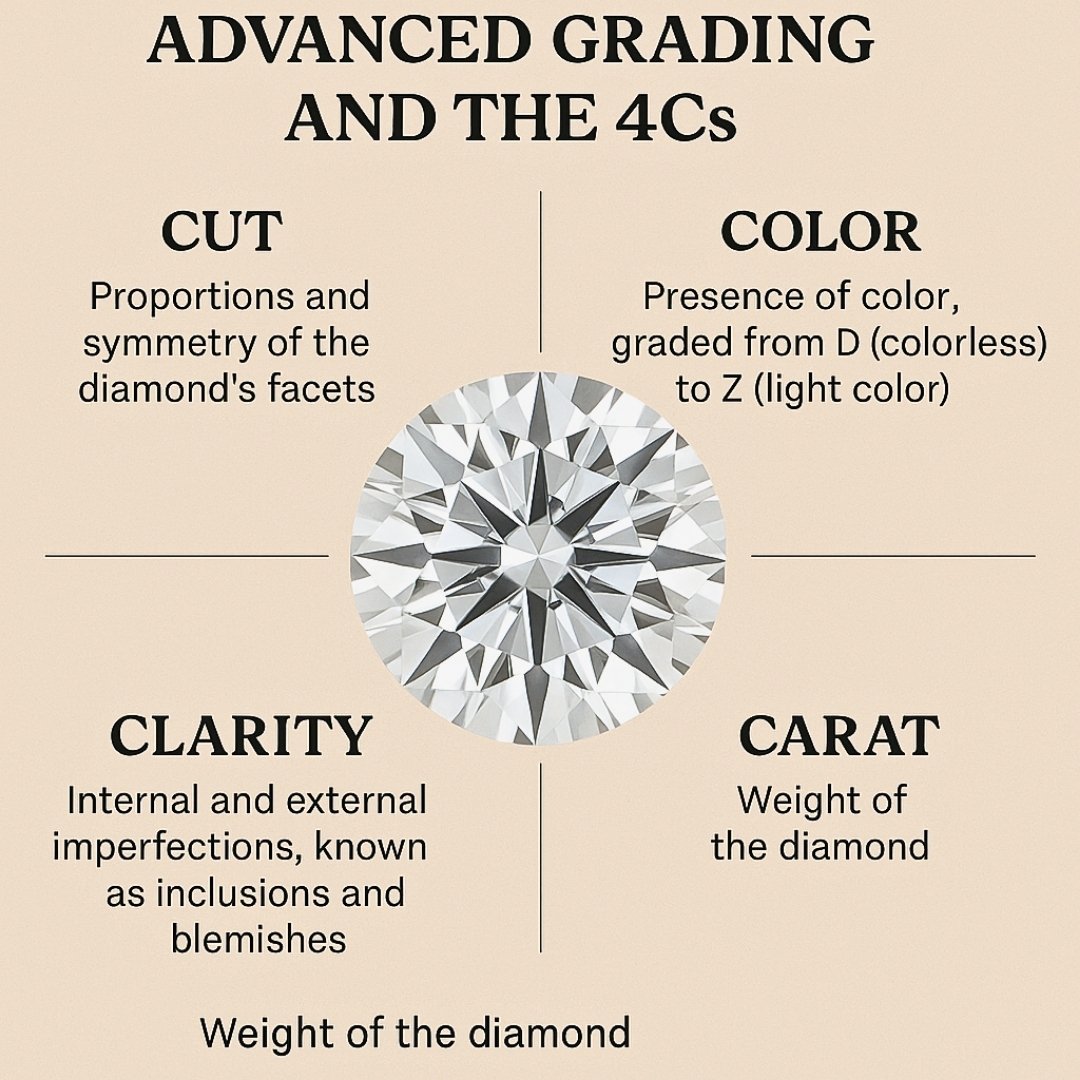

Section 2: Beyond the Basics: Advanced Grading and the 4Cs

While the 4Cs (Cut, Color, Clarity, and Carat) are the universal language of diamonds, CVD production introduces specific nuances that buyers must understand, particularly when dealing with the manufacturing methods commonly employed in India.

C1: Cut – The Non-Negotiable Quality Indicator

As noted, Cut is the most critical quality factor, as it is the only “C” determined by human skill and technology, not nature or the growth process.

What to demand from high-quality CVD:

- Grade: Insist on a Cut Grade of Excellent or Very Good (for rounds) or the highest grade achievable for fancy shapes. Anything lower compromises the diamond’s visual performance.

- Polish and Symmetry: These are key sub-components of the Cut grade. Look for Excellent in both. High-quality Indian polishing ensures surfaces are micro-smooth, which allows light to enter and exit cleanly, maximizing sparkle.

- Proportions: A premium CVD diamond will have perfect table, depth, girdle, and pavilion angles. A seller should be able to provide the proportions report, confirming the stone is optimized for light performance, not just weight.

C2: Color – Understanding Post-Growth Treatment

CVD diamonds are grown by depositing carbon atoms layer by layer from a hydrocarbon gas. During this process, especially when grown quickly for scale, trace elements can cause a slight, undesirable brownish tint in the resulting crystal.

What high-quality Indian manufacturers do:

- HPHT Post-Treatment: Most colorless and near-colorless CVD diamonds on the market undergo a post-growth treatment using High-Pressure/High-Temperature (HPHT) methods. This is an industry-accepted and permanent process that removes the brown tint, achieving the highly desirable D, E, F (colorless) or G, H, I, J (near-colorless) grades.

- Disclosure is Key: A reputable manufacturer must disclose this treatment on the grading report. If a D-color CVD diamond is offered at a surprisingly low price, it is almost certain to be HPHT-treated, which is perfectly acceptable but requires full transparency.

- Premium Untreated Stones: The rarest and most expensive CVD diamonds are those grown slowly and meticulously enough to achieve D-F color grades without any post-growth HPHT treatment. While rarer in the mass market, these stones are the pinnacle of CVD production and should be noted as “As-Grown” on the certificate.

C3: Clarity – Expecting Purity

Due to the controlled environment of the laboratory, CVD diamonds often achieve higher clarity grades than natural diamonds.

What to look for in high clarity CVD:

- Target Grades: VVS (Very Very Slightly Included) and VS (Very Slightly Included) are common and highly sought after. These grades ensure inclusions are invisible to the naked eye.

- Specific Inclusions: While all diamonds have clarity characteristics, CVD diamonds may exhibit unique inclusions like thin, dark, metallic-looking inclusions or unique internal graining patterns that are indicative of the growth process. These are not flaws but identifiers. The grading report should plot these minor characteristics.

- The Best Value: Diamonds graded VS2 or SI1 (Slightly Included) often represent the best value, as their inclusions are typically invisible without 10x magnification, yet they come at a lower cost than flawless stones.

C4: Carat Weight – The Price Driver

Carat simply measures the weight (1 carat = 200 milligrams). Unlike mined diamonds, where size is limited by nature, CVD technology allows Indian manufacturers to reliably grow larger rough stones.

Buyer Strategy: Because CVD offers significant cost savings (typically 60-70% less) compared to a natural diamond of comparable quality, smart buyers can prioritize cut and clarity, yet still afford a larger carat weight.

Section 3: The Ultimate Verification: Certification and Type IIa Purity

The true measure of a premium CVD diamond lies in its accompanying paperwork, which must go beyond the 4Cs to confirm origin, treatment status, and chemical type.

The Mandatory Certification Checklist

Never purchase a CVD diamond, especially from an overseas supplier, without a grading report from a globally recognized, independent gemological laboratory.

- Accepted Labs: You must insist on certification from the International Gemological Institute (IGI) or the Gemological Institute of America (GIA). These two labs are the industry standard for lab-grown diamonds, providing the most detailed and consistent reports.

- Origin Disclosure: The report must unambiguously state the origin, typically labeled as “Laboratory Grown Diamond” or “Lab-Created.”

- Laser Inscription Verification: High-quality stones will have a microscopic laser inscription on the girdle. This inscription includes the grading report number and often the term “Lab Grown.” Crucially, this number must match the number printed on the grading certificate. This is the first line of defense against substitution or misrepresentation.

- Treatment Disclosure: Verify the “Treatment” or “Post-Growth Treatment” section. As discussed, the disclosure of HPHT (High-Pressure/High-Temperature) is common for colorless CVD diamonds. If this field is blank, the stone is considered “As-Grown” and is typically higher-priced. Full disclosure indicates a trustworthy manufacturer.

The Chemical Gold Standard: Type IIa Purity

This is one of the most sophisticated checks for premium quality. Diamonds are chemically classified by the presence (or absence) of nitrogen impurities.

- Type IIa Diamonds: These are the most chemically pure diamonds, containing virtually no nitrogen atoms within the crystal structure. They account for only 1-2% of natural diamonds (like the famed Cullinan or Koh-i-Noor) but are the standard for high-quality CVD production.

- CVD and Purity: Because the CVD process is controlled, manufacturers in India can grow diamonds that are almost universally Type IIa. This purity is directly linked to superior optical transparency and brilliance. The grading report should either explicitly state “Type IIa” or show spectral analysis consistent with a Type IIa diamond. If you are aiming for the best, Type IIa purity is the hallmark of a premium CVD product.

Section 4: Vetting the Indian Manufacturer: Provenance and Transparency

Buying a high-quality CVD diamond is as much about the stone as it is about the seller’s ethics, technology, and quality control processes. When engaging with Indian manufacturers or their authorized resellers, vet them based on their operational practices.

1. Quality Control and Screening Protocols

A premium manufacturer will have strict internal Quality Control (QC) processes that mimic the standards used for mined diamonds. Ask about their protocols:

- Synthetic Detection: Top facilities utilize specialized machinery and synthetic detection scanners (often manufactured by companies like De Beers or HRD) to screen every polished diamond. This ensures that the production stream is clean and no non-diamond materials have been inadvertently introduced.

- Pre-Shipment Inspection (PSI): Quality-focused manufacturers employ a multi-stage inspection process, including DUPRO (During Production Check) and PSI. These checks look for physical defects, check for consistent craftsmanship, and confirm adherence to stated specifications, including proper secure setting and polishing. This goes beyond the diamond itself to include the final jewelry piece if applicable.

- Weight Verification: Precision in weight is non-negotiable. Look for evidence of rigorous weight and dimension verification using calibrated machinery.

2. Digital Transparency and Inventory Management

Modern, high-quality Indian diamantaires rely on technology to build trust with international buyers. Look for:

- Virtual Loupe Technology: The ability to provide high-definition, 360-degree videos of the diamond. This “Virtual Loupe” allows you to examine the cut, symmetry, and clarity characteristics (including the laser inscription) as if the diamond were in your hand.

- Real-Time Stock: Manufacturers with robust digital infrastructure offer real-time, live stock updates. This ensures the diamond you select online is 100% available and ready for immediate dispatch, reflecting efficient inventory management.

- Customization Capabilities: India’s manufacturing scale allows for bespoke requests. High-quality sellers can offer custom cuts, unique color grades (such as fancy pinks or blues), or private labeling/laser inscription as per your brand’s specific requirement.

3. Ethical and Sustainability Credentials

While all lab-grown diamonds are inherently conflict-free, premium Indian manufacturers often take this a step further by seeking broader sustainability credentials:

- Traceability: Look for companies offering detailed origin tracking—a full breakdown of the stone’s journey from the growth chamber to the final polish.

- Certification: Some manufacturers pursue third-party certifications (like BRC Certification) to confirm their ethical and sustainable production processes. Supporting these manufacturers aligns with the ethical value proposition of CVD diamonds.

Section 5: The Final Steps: The Trust Factor

Once you have analyzed the diamond’s 4Cs, reviewed the certification, and confirmed its Type IIa purity, the last step is to assess the manufacturer’s commitment to customer service and long-term partnership.

- Warranty and Returns: A reputable Indian manufacturer or retailer will offer a clear, comprehensive warranty covering any manufacturing defects. They must also provide a transparent return or exchange policy, allowing a reasonable inspection window for the stone upon arrival.

- Pricing Policy: High-quality manufacturers adhere to professional pricing standards, often using a “One Price Policy” globally for certified diamonds. While lab-grown diamonds offer value, be wary of prices that seem too low, as they may indicate compromises in the cut, polish, or clarity grades that were not captured in the primary certification.

- Industry Reputation: Check independent customer reviews, assess the company’s operational history, and seek recommendations within the jewelry industry. Longevity and a history of positive transactions are strong indicators of reliability.

Conclusion

The Indian diamond industry, with its perfect blend of generational craftsmanship and cutting-edge CVD technology, has set the new global standard for lab-grown diamond excellence.

To identify a truly high-quality CVD diamond, you must adopt a multi-layered approach. Focus relentlessly on securing an Excellent Cut grade, understand the necessary HPHT treatment to achieve colorless grades, and insist on IGI or GIA certification that confirms a Type IIa chemical composition and a matching laser inscription.

By applying this advanced framework, you move from being a general consumer to an expert procurement specialist, ensuring that the CVD diamond you source from India is a premium, brilliant, and ethically superior investment. Start your rigorous search today—the world’s most sophisticated diamonds are waiting.